The complicated harnessing of photo voltaic power to energy electrical automobiles continues to be comparatively untapped, however new options are being launched to make it a extra reasonably priced and mainstream know-how. However are vehicles powered by the rays of the solar actually the way forward for mobility?

Proper now, solar-power electrical car know-how stays a minority innovation, primarily as a result of concerned nature of power seize and energy switch. However there are various folks on the market who imagine it gained’t all the time be that method.

Proper now, solar-power electrical car know-how stays a minority innovation, primarily as a result of concerned nature of power seize and energy switch. However there are various folks on the market who imagine it gained’t all the time be that method.

A kind of folks is Jan Schiermeister, VP know-how at Sono Motors, though creating the know-how for on a regular basis use isn’t with out its setbacks. Sono Motors had been creating the Sion, a solar-powered EV with monocrystalline silicon cells built-in into its physique however needed to terminate this system in early 2023. That initiative was supposed on the market, so Sono Motors’ focus is now on business-to-business photo voltaic options, retrofitting and integrating its photo voltaic know-how onto third occasion automobiles. A complete of 25 prospects – together with Scania, Kögel and Chereau – are piloting its scalable photo voltaic know-how on quite a lot of car architectures.

“Now we have been working for years to understand polymer sandwich vehicle-integrated photo voltaic modules that may be made in nearly each three-dimensional form,” says Schiermeister. “The modules may be utilized on car sides, tailgate or hood, not solely on the roof, fulfilling necessities for the PV and automotive sectors,” he says. “Though recognized photovoltaic (PV) modules aren’t designed for static use circumstances and particularly not for automotive necessities, in regard to authorized complexities resembling crash habits or flammability.”

Due to this, implementation of automotive physique photo voltaic cells is a problem, as strict occupant security and pedestrian safety necessities must be met. “Shut cooperation with car OEMs is required and retrofitting is tougher,” says Georg Zurmühl, Sono Motors’ product supervisor. “Nonetheless, our car built-in photovoltaic (VIPV) know-how primarily based on automotive molding processes is exclusive, unlocking the potential for 3D-shaped photo voltaic physique panels.” Zurmühl provides that the excessive quantity manufacture, low cycle occasions and affordable prices are key advantages.

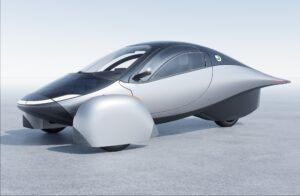

“You may’t have photo voltaic with out effectivity,” says Steve Fambro, co-founder and co-CEO of US photo voltaic EV start-up Aptera Motors. “The pursuit of effectivity first lets us do issues resembling photo voltaic mobility. However the know-how must be cell in addition to dependable, which provides a further layer of utility. In the event you took a photo voltaic panel and electronics IP we have already got and put it on an everyday automotive, it gained’t have any considerable affect.” Which is why Fambro believes a ground-up strategy is one of the best answer to leverage the know-how.

He explains that the sky-facing surfaces on the physique of Aptera’s first photo voltaic EV are clothed in photo voltaic polymer sandwich panels that use a proprietary know-how, which encapsulates the photo voltaic cell itself to guard it towards moisture and oxygen. Aptera has patents for using glass or plastic for the entrance and rear panel surfaces, and both materials can be utilized relying on the applying. “It additionally must be light-weight and has to provide energy when unfold throughout the car when a part of it’s shaded or coated,” says Fambro. “Growing curved photo voltaic panels for automobiles which might be light-weight sufficient to fabricate whereas capable of face up to hail strikes, vibration and thermal biking, has been the primary focus of our IP.”

As much as 700 watts of steady charging energy is launched by Aptera’s photo voltaic panels, sufficient for as much as 40 miles of vary per day. Over the course of a 12 months, Fambro believes a location resembling San Diego has the potential to seize as a lot as 11,000 miles’ value of photo voltaic power – 4kWh per day. Batteries of 25, 40, 60 or 100kWh are mooted, utilizing Lithium Nickel-Cobalt-Aluminum Oxide (NCA) chemistry, and EVE Vitality Co’s 21700 NMC 811 cylindrical cells. The Launch Version automotive may have the 40kWh battery – really 42kWh usable, 45kWh gross capability – with as much as 400 miles of vary and a projected effectivity goal of as much as 10mpkWh (100Wh/mile). Liquid-cooling allows dependable 40-60kW NACS quick charging.

Rays of hope

Rays of hope

With a historical past in growth of solar-powered EVs, a group from the Eindhoven College of Know-how has just lately accomplished in depth testing in Morocco of the street authorized Stella Terra, a solar-powered off-road EV with the potential to journey 390 miles on a sunny day. Niels van den Broek, a Photo voltaic Crew Eindhoven electrical engineer, says common photo voltaic panels couldn’t be used, as they might compromise aerodynamics and add pointless weight. “We opted for versatile panels – consisting of a generally used plastic front and back sheet, housing the photo voltaic cells with adhesive in-between – that might be positioned on our single-curved bonnet and roof,” he says. “The photo voltaic cells are comparatively commonplace, with a excessive effectivity of 23.7%. Employed in home photo voltaic panels, our challenge reveals even with ‘regular’ photo voltaic cells, it’s possible to make a automotive absolutely powered by the solar.”

Whereas specialist know-how isn’t all the time important, a extra proprietary strategy is best capable of make use of photo voltaic power in more and more concentrated methods. Schiermeister explains Sono’s distinctive microcontroller or digital management unit (MCU) has each a excessive effectivity and high-voltage capabilities, enabling a extremely environment friendly photo voltaic yield whereas driving. “Our energy electronics is a specifically designed multi-channel idea, combining a number of most energy level trackers (MPPTs) in a single field. This permits for each environment friendly and impartial operation of a number of photo voltaic modules with completely different orientations in direction of the solar. It adapts tremendous shortly to fast-changing solar radiation circumstances, key for cell photo voltaic purposes the place each harvested Wh is efficacious,” Schiermeister elaborates.

Van den Broek explains Photo voltaic Crew Eindhoven’s greatest problem was the absence of a 400V MPPT. “With out an MPPT, photo voltaic panels on a automotive might be much less efficient and even ineffective. In Stella Terra, the battery voltage varies between 280 to 400V, relying on the state of cost (SoC). Nonetheless, the voltage output of our photo voltaic teams varies between 50-90V. This means an influence converter must be positioned between the photo voltaic teams and our HV system; in any other case, the present generated by the photo voltaic panels is not going to move into the battery. Consider it like water; water solely flows from the next level to a decrease level – present solely flows from greater present to decrease present,” he says.

One other impediment in making a solar-powered car is the relative contribution of solar energy to the overall energy utilized by the car itself. “Putting just a few photo voltaic panels on a car could solely produce sufficient power for a small proportion of the overall power utilization,” says Van den Broek. “Our objective was to create a solar-powered car that would drive solely on photo voltaic power. This required vital effort to design a light-weight and aerodynamic automotive that consumes as little power as attainable.”

A light-weight construction not solely advantages effectivity, but additionally the photo voltaic power know-how itself. Aptera makes use of a type of carbon composite with a really excessive fee of manufacturing. Impressed by plane with a low frontal space and small cross-section, the automotive has a teardrop form and an aluminum stomach pan. Two entrance wheels and one rear wheel support the projected effectivity. “There’s one much less wheel so there’s a big quantity of construction that’s not wanted to help a fourth quarter,” Fambro explains. A low drag coefficient of 0.13 means the Aptera’s physique is as optimized as it may be, too.

Additional efficiencies may be made by means of using direct-drive powertrains. “ how effectivity stacks up, in-wheel motors are the following step,” says Fambro. Aptera has been working with direct drive powertrain specialist Elaphe to co-design its present motor, which is a spinoff of what the corporate produces. “Nonetheless, it has been redesigned to be absolutely the best in our energy regime, for torque, rpm and typical loading,” says Fambro. With an eye fixed on even additional efficiencies, silicon carbide inverter know-how can be being evaluated.

Right here comes the solar

Right here comes the solar

In-wheel motors from Protean had been chosen for the Stella Terra. “In-hub motors remove the necessity for drive shafts, enhancing aerodynamics,” says says Van den Broek. “Protean motors even have as much as 93% effectivity, encompassing motor and inverter, and have the very best IP-rating attainable. In addition they adhere to the ISO26262 purposeful security commonplace, instilling confidence of their reliability. Housing the motor and inverter in a single unit considerably eased incorporation of the motors into the Stella Terra’s electrical structure.” A 16-strong group started growth of the Stella Terra in September 2022. A 12 months later, with an expanded group of twenty-two, the off-road automotive was offered in its ultimate kind. Exams on the power utilization of various off-road surfaces offered priceless insights, making certain the EV might full its difficult 620-mile (1,000km) tour solely on solar energy.

Because of their excessive power demand used for shoppers resembling infotainment screens, HVAC methods, and repeated door opening and shutting features, buses and supply service automobiles at the moment seem to learn essentially the most from photo voltaic know-how. “Diesel buses burn gas for these features and profit drastically if this gas is changed by solar energy,” says Zurmühl. “E-buses and cooled items supply automobiles lose driving vary because the battery has to energy the shoppers, and for this reason photo voltaic integration is so helpful.” Photo voltaic additionally advantages hybrid car purposes, however the features are much less marked and rely on particular person utilization circumstances.

To see solar-powered EV know-how develop into extra widespread, Fambro believes {that a} mass adoption by trade could be wanted, accompanied by extra environment friendly platforms. “That comes again to the ground-up strategy, which actually must be a ground-up rethink of what environment friendly transportation seems to be like,” he says, believing different low velocity mobility markets away from the passenger automotive sector have extra available alternatives.

Van den Broek thinks that each EV sector can profit from photo voltaic know-how, however that photo voltaic integration does come at a value, and a return on funding is anticipated. “Moreover, there are geographical variations, with some areas having larger solar energy manufacturing potential than others,” he says. It is because of this Van den Broek views photo voltaic integration primarily, for now, as a supplemental choice.

But Schiermeister feels all sectors the place there’s enough consumption of power and the price of power and vary performs a task will profit. “Quick time period, industrial automobiles resembling buses and refrigerated automobiles will profit as they’ve a further excessive power demand over the excessive power demand for driving,” he says. “As they’ve big surfaces that may be coated with photo voltaic panels, the implementation is comparatively simple.” Whereas believes that within the mid-term, integration into passenger automotive physique panels will profit this sector, unlocking big potential for greater photo voltaic power yields per car, Schiermeister concedes that photo voltaic could all the time be an add-on. “It should enrich conventional EVs and never problem them. OEMs could supply non-obligatory photo voltaic options, however with growing efficiencies and sinking prices of photo voltaic cells and since power from the solar is free – after the preliminary funding, photo voltaic integration has the potential to develop into a broad EV utility.”

Fambro says first Aptera deliveries are projected to reach 9 to 12 months after the closure of the corporate’s main funding spherical which at the moment stays open, however how far into the longer term will photo voltaic know-how begin to problem extra conventional EV purposes? “We try to remain 5-10 years forward of the market, demanding specialist know-how for our photo voltaic integration,” says Van den Broek. “Our imaginative and prescient is that inside 10 years, most automotive corporations will supply an choice to combine photo voltaic panels on sure fashions, with an growing variety of automobiles actively utilizing photo voltaic panels to cost their batteries.”