Progressive product pinpoints EV battery hotspots, improves security and extends battery life

Lithium batteries supply the very best energy density in contrast with different battery chemistries. Lithium batteries can retailer extra vitality in a smaller, light-weight package deal than another sort of battery. Because of this, Lithium-based batteries are the battery sort of alternative for every type of electrical automobiles (EVs). Sadly, lithium batteries have a number of downsides. They will endure thermal runaway if broken, below very excessive masses, overcharged, or uncovered to excessive temperatures. Thermal runaway can generate sufficient warmth to ignite the electrolyte and trigger a hearth or an explosion of a battery pack. Such situations can severely injury the battery pack and the EV and probably put the passengers in danger.

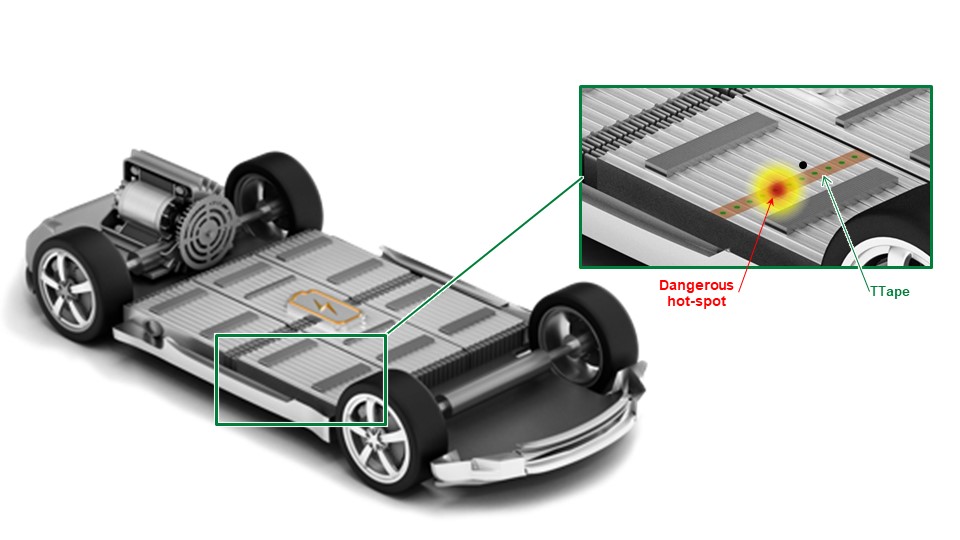

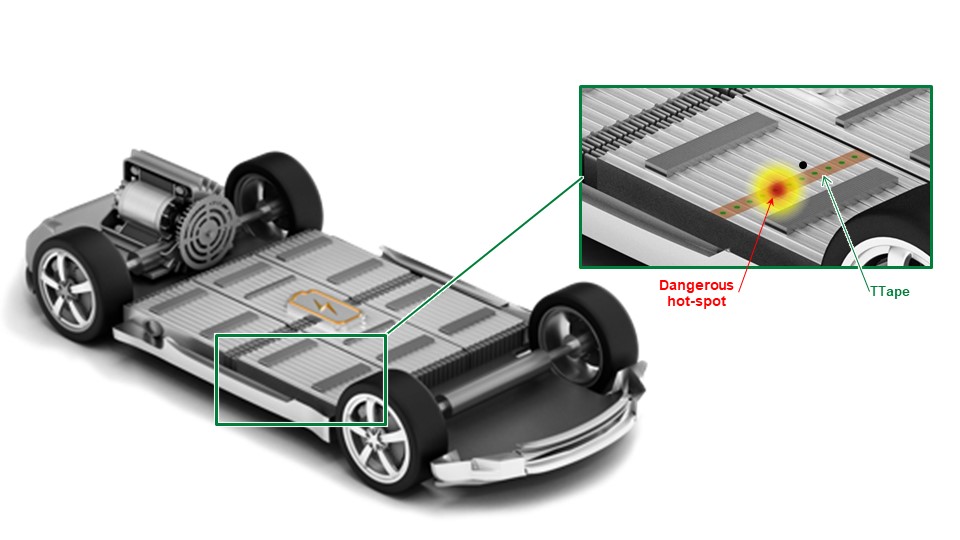

A brand new know-how that mitigates the danger of battery thermal runaway is now out there. The most recent know-how developed by Littelfuse, the TTape™ Distributed Temperature Monitoring System, allows early detection of localized battery cell overheating. The revolutionary platform contributes to extending battery life and enhancing the security of battery installations. TTape is a strip of tape with quite a few intently spaced temperature indicators. Not like a discrete thermistor, TTape adheres to battery cells and conforms to the form of the cells, enabling excessive density monitoring of areas on a battery pack. The temperature indicating sensors rapidly detect a cell sizzling spot stopping battery thermal runaway. With particular person thermistors whose measurement limits the variety of detection areas and prevents shut spacing, a battery cell sizzling spot that isn’t close to the placement of a thermistor may rise to a harmful degree. TTape solves the issue of being unable to detect battery cell sizzling spots rapidly.

This text introduces the reader to the advantages of the TTape Distributed Temperature Monitoring System and particulars the product. As well as, a pattern circuit illustrates utilization in a safety scheme. Design engineers will discover TTape a superb and simplified part for making certain lithium-ion batteries have most life and are protected to function.

Description of TTape

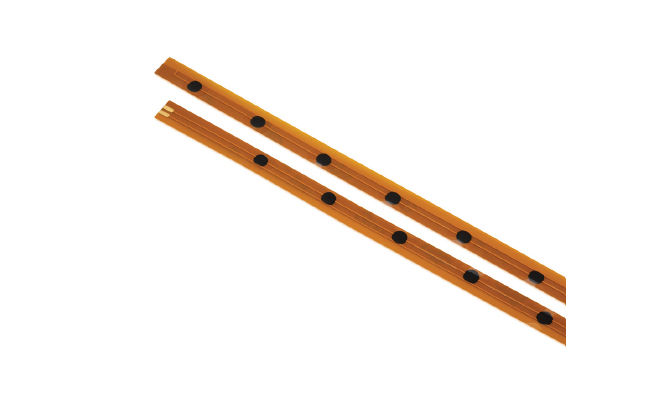

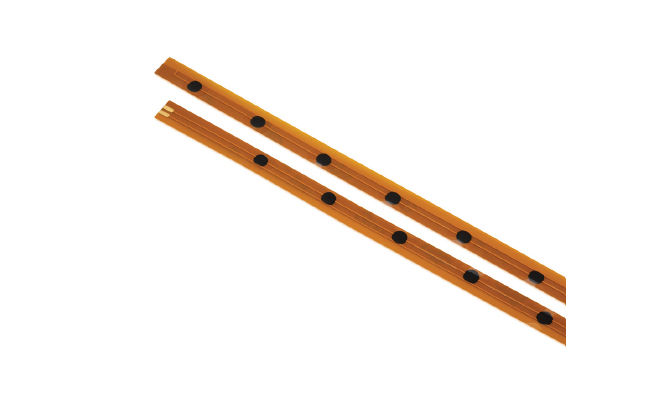

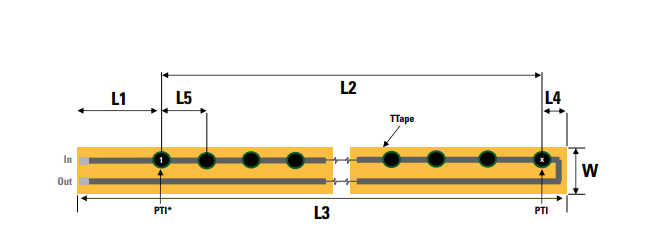

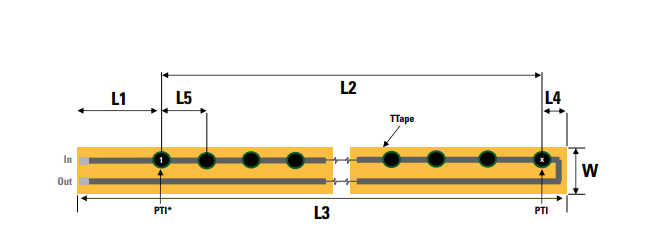

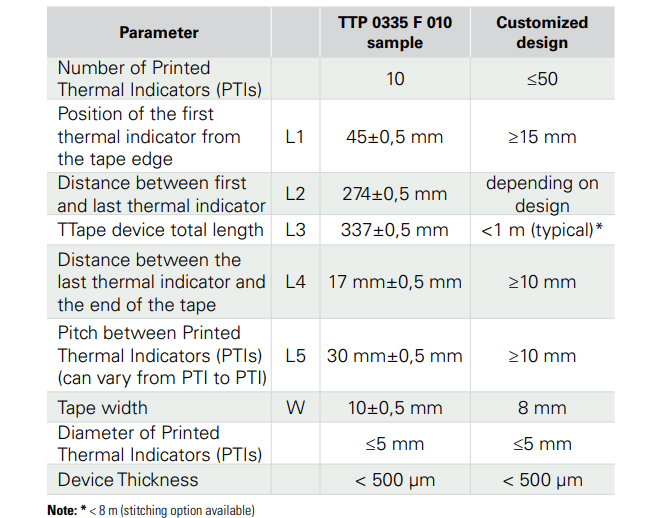

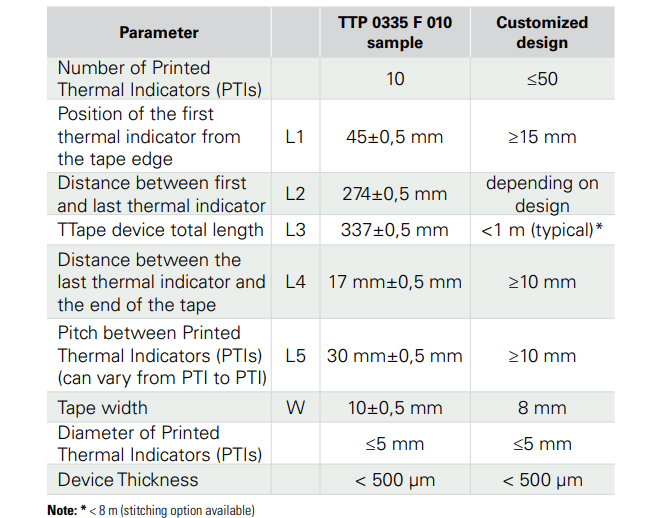

TTape is a versatile, skinny band of printed temperature indicators spaced intently collectively for max spatially resolved temperature monitoring. Its thickness is lower than 500 µm which permits it to adapt to any battery pack form. Determine 1 exhibits the TTape strip with the printed temperature indicators (PTIs).

The printed temperature indicators are small dots of polymer constructive temperature coefficient materials. The PTIs are linked in collection. When a PTI detects a temperature above the edge degree, its resistance will increase by an element of over 1000.

Determine 2 gives the dimensional particulars on the TTape Distributed Temperature Monitoring System. Temperature sensors could be spaced round 10 mm aside. The TTape has choices for a slim width of both 8 mm or 10 mm and a regular size of 337 mm. Customized designs could be so long as 1 m. Strain-sensitive adhesives bond the TTape to a floor. The adhesive permits bonding to steel, polyamide, PET, and polyimide surfaces.

A normal tape size of 337 mm consists of ten printed thermal indicators. Customized designs can include as much as 50 of the PTIs. The printed thermal indicators have a most diameter of 5 mm with a regular spacing of 30 mm. The slim spacing between the PTIs permits elevated spatial decision for monitoring the temperature of all cells on the battery pack. Discrete temperature sensors can’t obtain such shut monitoring of all particular person battery cells. Moreover, with a thickness of below 500 µm, the TTape can conform to the irregular floor of the battery pack and have direct contact with the person battery pack cells.

The TTape connects to an digital circuit with a 2-wire solder pad interface. Figures 1 and a couple of present the 2 solder pads, and Determine 2 defines their perform.

The TTape has a visit temperature setpoint of 58 ± 3° C for early overheating detection earlier than a battery cell can attain a harmful temperature degree. Lithium-ion and different battery chemistries can cost and discharge at temperatures below 60° C earlier than typical battery administration circuits take motion. The battery administration system will interrupt the load or the charging energy on the battery pack when a temperature above 60° C is detected. Typically, the 58° C setpoint tolerates the battery pack temperature fluctuations that happen when a battery pack is below load or re-charged. The printed thermal indicators have a response time of below one second. If a battery pack temperature exceeds the nominal 58° C threshold for longer than one second, the TTape temperature monitor will reply.

To keep away from speedy on-off biking close to the edge temperature, the TTape PTI materials has a hysteresis attribute which prevents put on on essential system parts and avoids false alarms. This design method ensures the system responds solely when there’s a real overtemperature situation, contributing to the security and sturdiness of the battery pack.

Circuit implementation

TTape works in TTL-level l, 5 V circuits, or 3.3 V logic circuits. Determine 3 exhibits a advisable circuit configuration to be used with a TTape monitor. VT is a logic excessive when the TTape printed thermal indicators detect a temperature exceeding 58° C and change to a excessive resistance. VT is a logic low when the temperature is beneath 58° C or if the temperature has exceeded the edge temperature and has fallen beneath 42° C. The printed thermal indicators exhibit a hysteresis impact of roughly 16° C as soon as the edge temperature is exceeded. The correct aspect of Determine 3 presents the hysteresis curve of the TTape machine.

The logic circuit is a straightforward circuit using a advisable worth of RP as 200 KΩ. VT can present a sign to an A/D converter in a microcontroller. When the TTape just isn’t detecting a battery sizzling spot, the 5 V circuit attracts round 25 µA to eat solely 125 µW. The TTape wants just one A/D enter line on the microcontroller to transmit the temperature state of the battery cells. The microcontroller can both be part of the battery administration system or be an interface to it.

Comparability with discrete thermistor temperature monitoring

With solely 30 mm between the printed thermal-indicating sensors and a skinny adhesive tape type issue that may conform to any floor, the TTape can detect a battery cell temperature rise earlier than a discrete sensor can except the temperature rise is correct below the discrete sensor. Determine 4 illustrates this example. If a thermistor is one cell away from an overheating cell, it may take over two minutes for the thermistor to reply to the excessive temperature situation. With PTIs on every cell, the response is below one second.

Not like a NTC sensor, the TTape temperature monitoring platform doesn’t want calibration since it’s basically a two-state machine. As well as, the electronics that course of the TTape sensors don’t require a temperature conversion calibration desk.

As a conforming tape, the TTape consumes negligible house on the battery pack. TTape allows simple set up and permits monitoring of any battery pack development. Determine 5 exhibits an instance set up of a TTape monitoring strip on a battery pack.

Excessive-density monitoring for enhanced security

The TTape Temperature Monitoring Platform presents designers with the distinctive skill to have extremely compact temperature monitoring on every group of cells in an EV battery. The high-density monitoring minimizes untimely ageing by detecting and stopping temperature sizzling spots on particular person cells or a gaggle of cells. This low-cost, minimal space-consuming answer gives enhanced security and prolonged battery cell life. Moreover, the TTape monitoring machine is AEC-Q200 certified to be used in automotive automobiles.

For extra info on the TTape Distributed Temperature Monitoring Platform together with set up particulars and circuit implementation, see the TTape™ Distributed Temperature Monitoring System Software Word.

To acquire technical help, go to the TTape product web page and get in touch with Littelfuse at www.littelfuse.com.