Sponsored by Hioki.

A key problem in growing Battery Electrical Autos (BEVs) is extending the driving vary by improved power effectivity. In contrast to fossil fuels, batteries have a decrease power density, necessitating large-capacity batteries to match the vary of inside combustion engines, which inadvertently will increase automobile weight and reduces power effectivity. Thus, there’s a urgent want for BEVs to attain longer ranges with fewer batteries.

Enhancing driving vary with fewer batteries hinges on bettering power effectivity by way of high-efficiency and miniaturized powertrains. Excessive effectivity reduces powertrain losses, whereas miniaturization cuts automobile weight and driving losses. Due to this fact, excessive effectivity and miniaturization of motor drive techniques are very important in vehicle electrification. This requires correct measurement of the enter/output energy of inverters and motor energy to understand effectivity and losses.

Adopting wide-bandgap semiconductors like SiC (Silicon Carbide) and GaN (Gallium Nitride) has just lately elevated inverter switching frequencies, reducing losses and presenting new alternatives for inverter design and efficiency analysis. Nonetheless, this progress introduces new measurement challenges, creating a requirement for wideband and high-precision energy measurements that conventional strategies can not fulfill. Discover how we deal with these rising challenges and revolutionize BEV growth.

The Problem

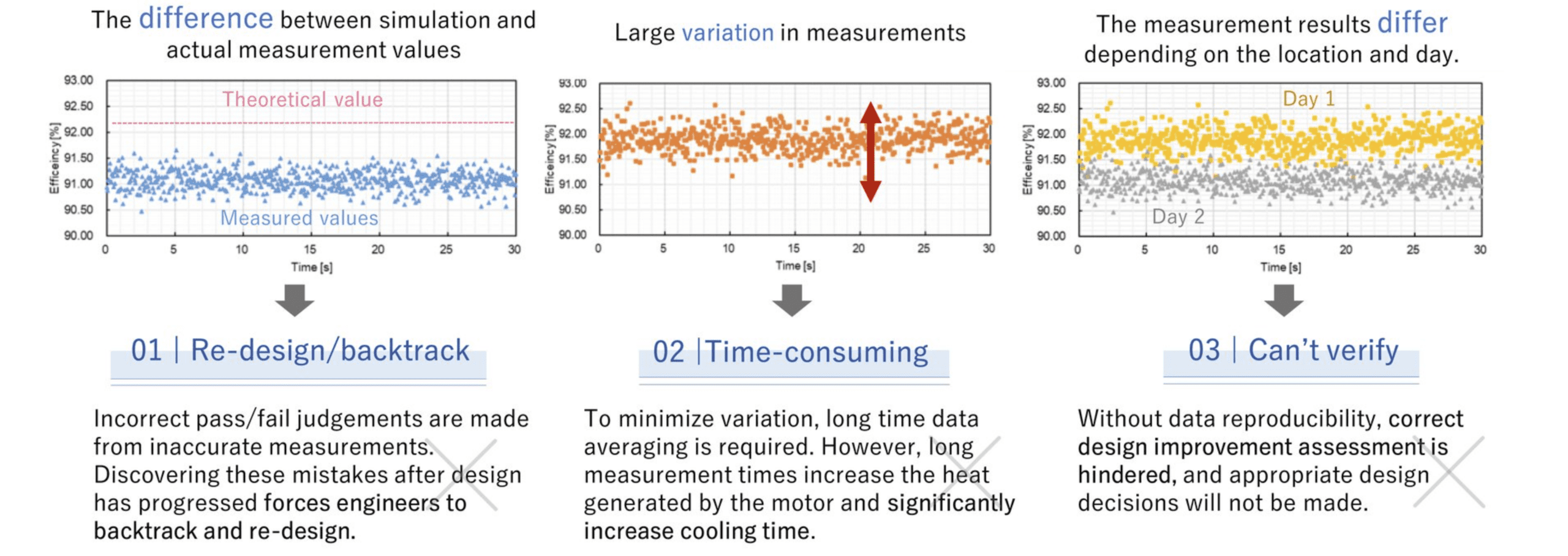

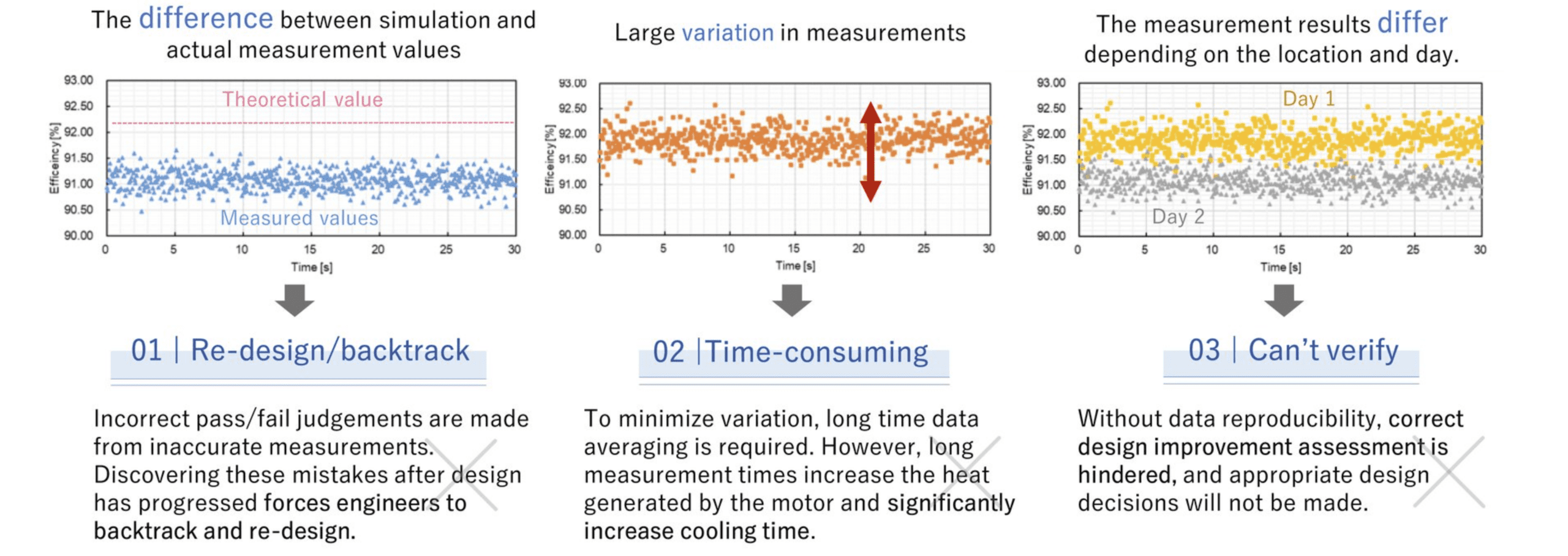

EV engineers on the entrance line of bettering inverter and motor effectivity regularly face a number of important challenges:

- Discrepancies between simulations and precise measurements: Theoretical fashions and real-world operation can differ, complicating design optimization.

- Measurement variability: Inconsistent knowledge underneath similar circumstances and differing outcomes based mostly on environmental elements can hinder reliability.

- Excessive-frequency measurement errors: Typical strategies battle with errors because of high-frequency switching frequencies in inverters, making it tough to acquire exact readings.

These challenges are largely because of measurement errors in high-frequency parts launched by the switching frequency of inverters. Inverter voltage and present waveforms will be segmented into two major frequency bands: the basic wave and its harmonic parts at 1 kHz or decrease and the switching frequency and its harmonic parts starting from a number of tens of kHz to a number of a whole bunch of kHz. Whereas common energy analyzers can precisely measure the decrease frequency band, they battle with the upper frequency band, resulting in important measurement errors. Because of this, precisely measuring high-frequency energy is essential in inverter growth, and appropriate measuring devices able to dealing with such measurements are important.

Assembly Trendy Inverter Wants

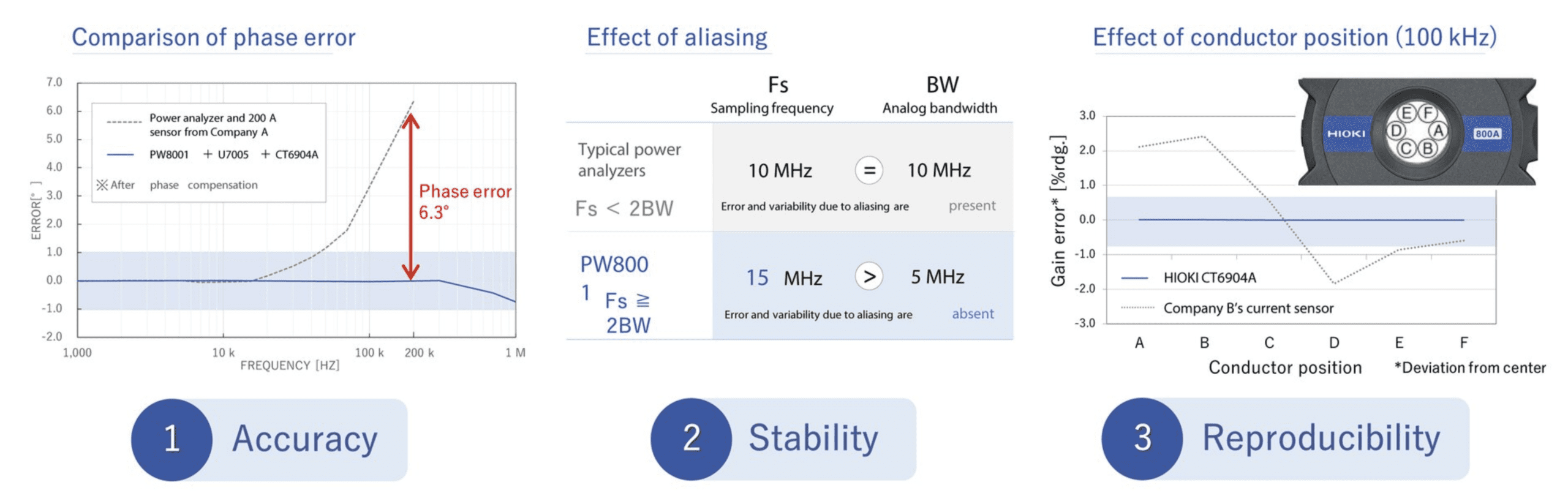

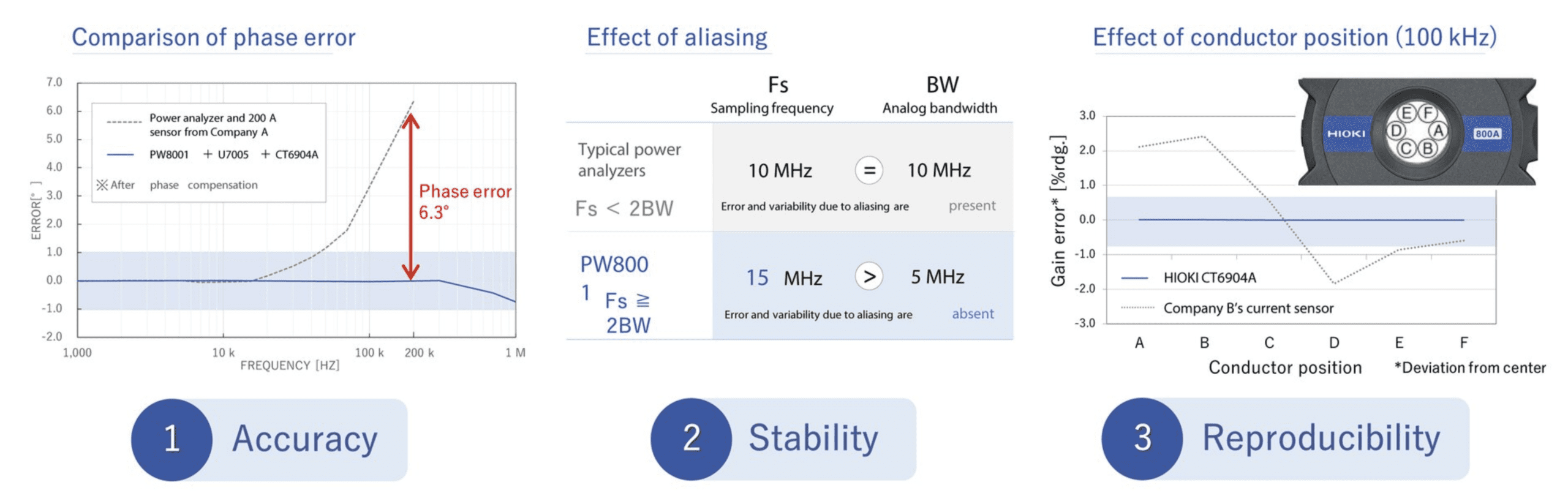

1. Accuracy

One of the crucial important contributors to measurement errors in high-frequency energy is part error. Conventional energy analyzers paired with customary present sensors typically introduce substantial part errors at excessive frequencies, hampering the precision of measurements for switching frequencies and their harmonic parts. Nonetheless, Hioki has the benefit of growing its present sensors, permitting for a complete understanding of their distinctive traits. This deep information permits distinctive part correction, making certain correct measurements even in high-frequency domains. This prowess considerably elevates the accuracy of evaluating the high-frequency traits of inverter and motor drive techniques, bolstering the reliability of growth and efficiency assessments.

2. Stability

A key contributor to measurement instability is aliasing. Basic energy analyzers, with a sampling frequency of 10 MHz and a frequency band of 10 MHz, fall wanting the required sampling frequency—at the very least double the frequency band for exact measurements—resulting in aliasing errors. Conversely, HIOKI’s PW8001 boasts a powerful 15 MHz sampling frequency, supporting wideband measurement of 5 MHz and successfully stopping aliasing. This ensures constant and dependable outcomes, even throughout prolonged measurement intervals.

3. Reproducibility

Basic present sensors might exhibit fluctuating measurement values in high-frequency ranges because of the affect of conductor place. If measurement values differ every time, it could be because of misalignment of the conductor place. HIOKI’s present sensors make use of a novel coil and defend construction, enabling measurements that aren’t affected by conductor place even in high-frequency ranges. This innovation permits for reproducible and correct measurements.

Elevate Your EV Initiatives

Hioki’s PW8001 units itself aside from conventional testers by offering correct, secure, and reproducible high-frequency energy measurements. For EV engineers and fanatics devoted to advancing EV expertise, the PW8001 is an indispensable instrument that ensures precision and reliability in powertrain growth.

Discover our options to be taught extra about future-proofing your powertrain check services and embrace the electrifying way forward for mobility.