- Stellantis upgraded its wind tunnel to the tune of $29.5 million

- The upgrades targeted on aero effectivity to assist with EV vary

- What used to take hours can now take minutes to vary with the current wind tunnel upgrades

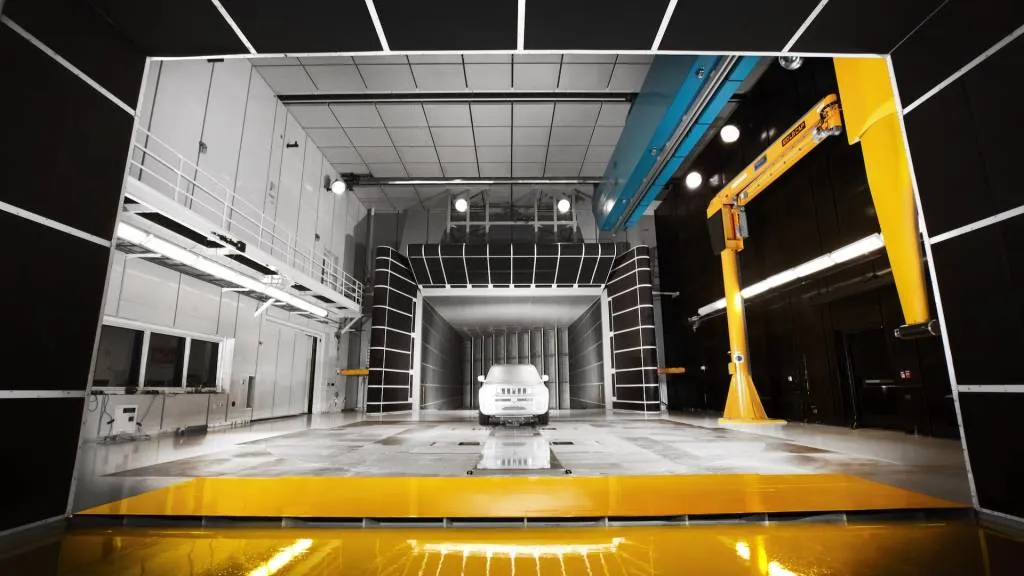

Stellantis on Wednesday unveiled a $29.5 million improve of the wind tunnel at its predominant analysis and growth facility in Auburn Hills, Michigan, giving engineers an enhanced software to additional enhance effectivity and EV vary.

Upgrades to the wind tunnel, which has been in steady operation since 2002, embody provisions for particular measurements of airflow resistance round wheels and tires, Stellantis stated, including that wheels and tires can account for as much as 10% of real-world aerodynamic drag.

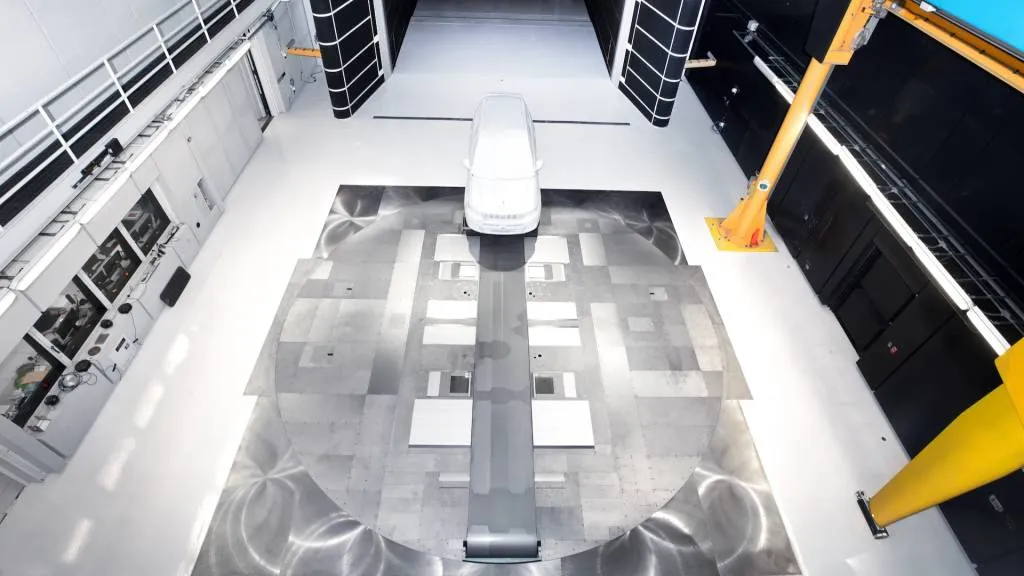

Automobiles stay static, with belts suspended on cushions of air turning all 4 wheels. A fifth transferring belt represents the impact of journey over a highway floor. Compressed air drives the belts at speeds as much as 140 mph, whereas the tunnel is able to producing wind speeds of as much as 160 mph, in accordance with Stellantis. The automaker makes use of related wind-tunnel expertise at different services globally, however the Michigan facility can accommodate bigger automobiles—together with EVs based mostly on the STLA Giant and STLA Body platforms.

Stellantis wind tunnel in Auburn Hills, Michigan

Elevated automation additionally implies that modifications of wheelbase and monitor that may take as much as two hours in typical wind tunnels can now be carried out in minutes, in accordance with Stellantis. This lets the wind tunnel proceed to behave as a significant complement to digital simulations.

“This equipment is a superb addition to digital instruments, which can not account for components comparable to tire deformation that may compromise aerodynamics,” Mark Champine, head of Stellantis’ North American engineering technical facilities, stated in a press release. “With this expertise we will replicate such situations and seize real-time knowledge to discover options.”

The wind tunnel is a part of an estimated $85 million dedication to facility upgrades laid out in a 2019 Stellantis contract with the UAW. Nonetheless, the automaker can be reportedly seeking to promote its Arizona proving grounds.

Stellantis wind tunnel in Auburn Hills, Michigan

The necessity to maximize EV vary with out additional rising battery-pack sizes has revived a century-old obsession with aerodynamics—one which Stellantis is aware of. The Chrysler Airflow debuted in 1934 with wind-tunnel-tested styling that proved controversial on the time. The Airflow title was revived in 2022 for an electrical SUV idea, though it is nonetheless unclear whether or not that car or a next-generation minivan would be the Chrysler model’s first EV.

Additionally of aerodynamic notice is the 2024 Dodge Charger Daytona, based mostly on the STLA Giant platform and in addition getting used to check solid-state batteries. The electrical muscle automotive makes use of an modern entrance airfoil to reconcile the blunt entrance finish harking back to the basic 1968 Charger with trendy aero necessities. The Daytona title, which denotes all-electric fashions, additionally references the Charger Daytona race automotive, which used a pointed nostril cone and tall rear wing to reduce aerodynamic drag on NASCAR oval tracks.

Stellantis is focusing on 50% U.S. EV gross sales and 100% European EV gross sales by 2030, with 75 fashions globally by that point.