Researchers at Harvard College have developed a strong state battery that may be recharged in 10 minutes, and now it’s acquired Sequence A funding to scale manufacturing.

October 23 replace: Adden Power has raised $15 million in a Sequence A spherical led by At One Ventures with participation from Primavera Capital Group, Rhapsody Enterprise Companions, and MassVentures to scale manufacturing and convey strong state battery know-how to automobile producers.

The corporate will use the funding to assemble a roll-to-roll pilot line manufacturing facility at its headquarters in Waltham, Massachusetts.

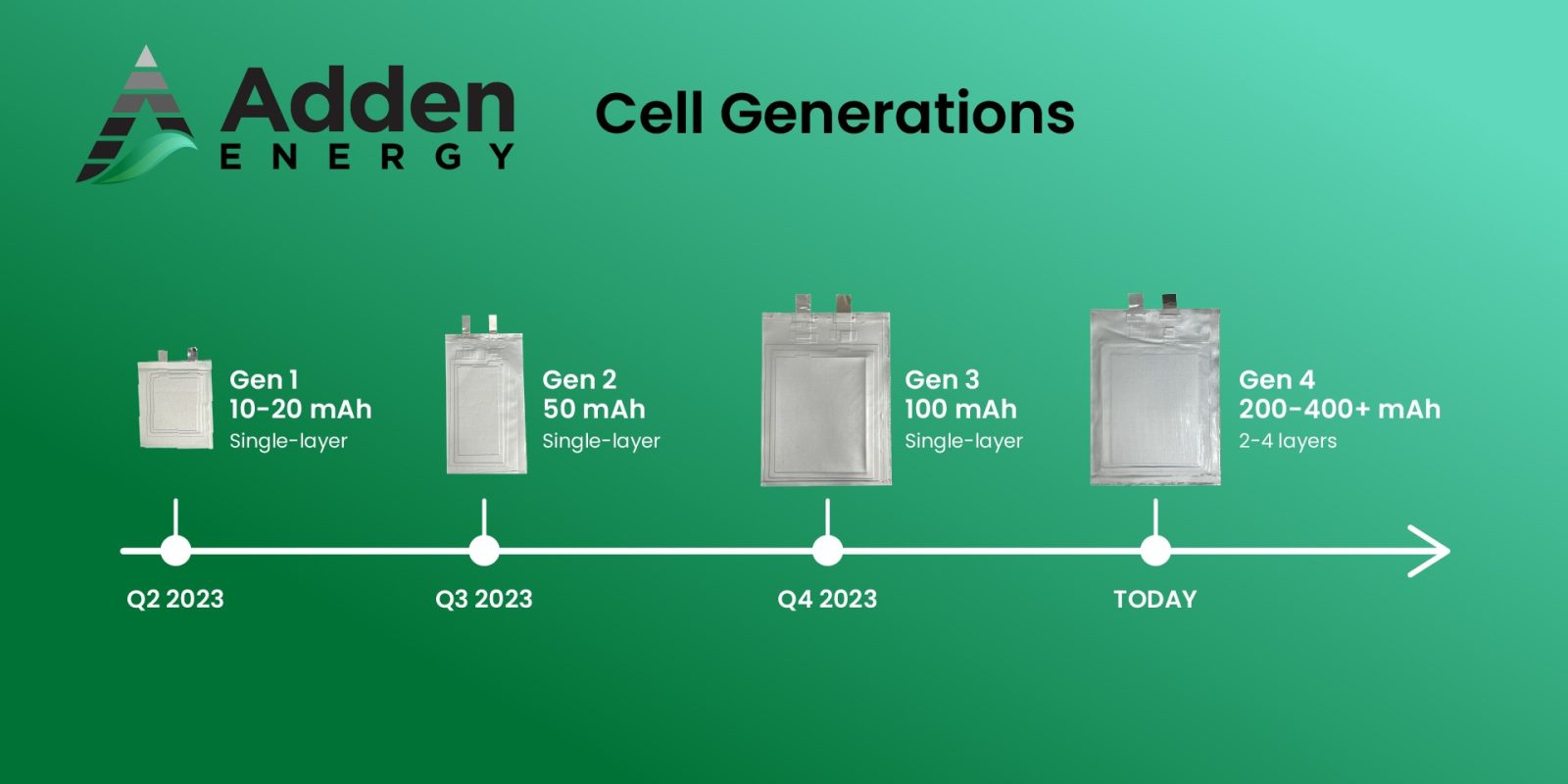

Adden Power has already demonstrated know-how that may ship its battery in EV-compatible, commercially appropriate pouch cell form-factors; this Sequence A-funded manufacturing line will allow it to scale the scale of the batteries 100x.

Laurie Menoud, associate at At One Ventures and board member at Adden Power, stated, “Our funding on this know-how is a sign of how essential we all know this to be, and it’s additionally our confidence degree in Adden Power’s means to win market share by means of aggressive unit economics. With the added power density of lithium metallic anodes, the fee per kilowatt hour goes to drop by 30%, and that’s going to be a big driver of adoption.”

Adden Power says its next-generation batteries are on observe to succeed in the aim of EV parity with inner combustion engines by 2028.

Harvard’s newest solid-state battery breakthrough

January 15, 2024: The lithium metallic battery researchers developed on the Harvard John A. Paulson Faculty of Engineering and Utilized Sciences (SEAS) may also be charged and discharged no less than 6,000 occasions — greater than some other pouch battery cell.

The analysis revealed in Nature Supplies describes a brand new option to make solid-state batteries with a lithium metallic anode. Xin Li, Affiliate Professor of Supplies Science at SEAS and senior creator of the paper, stated:

Lithium metallic anode batteries are thought-about the holy grail of batteries as a result of they’ve ten occasions the capability of economic graphite anodes and will drastically improve the driving distance of electrical autos.

Our analysis is a crucial step towards extra sensible solid-state batteries for industrial and industrial functions.

One of many greatest challenges in designing solid-state batteries is the formation of dendrites on the floor of the anode. Dendrites are projections of metallic that may construct up on the lithium floor and develop like roots into the electrolyte. They pierce the barrier that separates the anode and cathode, inflicting the battery to brief and even catch hearth.

The dendrites kind when lithium ions transfer from the cathode to the anode throughout charging, attaching to the floor of the anode in a course of referred to as plating. That creates an uneven, non-homogeneous floor on the anode, and permits dendrites to take root.

When discharged, that plaque-like coating must be stripped from the anode, and when plating is uneven, the stripping course of might be sluggish and lead to potholes that induce much more uneven plating within the subsequent cost.

In 2021, the crew designed a multilayer battery that sandwiched totally different supplies of various stabilities between the anode and cathode. This design prevented the penetration of lithium dendrites by controlling and containing them – however it didn’t cease them altogether.

However on this newest analysis, the researchers cease dendrites from forming through the use of micron-sized silicon particles within the anode to constrict the lithiation response and facilitate homogeneous plating of a thick layer of lithium metallic.

Within the Harvard researchers’ design, when lithium ions transfer from the cathode to the anode throughout charging, the lithiation response is constricted on the shallow floor and the ions connect to the floor of the silicon particle, however don’t penetrate additional.

“In our design, lithium metallic will get wrapped across the silicon particle, like a tough chocolate shell round a hazelnut core in a chocolate truffle,” stated Li.

And, as a result of plating and stripping can occur rapidly on a good floor, the battery can recharge in about 10 minutes.

The researchers constructed a postage stamp-sized pouch cell model of the battery, which is 10 to twenty occasions bigger than the coin cell made in most college labs. The solid-state battery retained 80% of its capability after 6,000 cycles, outperforming different pouch cell batteries available on the market at the moment.

Harvard Workplace of Know-how Improvement licensed the know-how to Adden Power, a Harvard spinoff firm cofounded by Li and three Harvard alumni. Adden Power has scaled up the know-how to construct a sensible phone-sized pouch cell battery.

Electrek’s Take

That is yet one more milestone achieved within the solid-state battery saga. The last word problem continues to be bringing them to mass-production at a lower cost than lithium-ion batteries. That would be the actual game-changer for EVs.

If you happen to’re an electrical automobile proprietor, cost up your automobile at dwelling with rooftop photo voltaic panels. To ensure you discover a trusted, dependable photo voltaic installer close to you that provides aggressive pricing on photo voltaic, try EnergySage, a free service that makes it straightforward so that you can go photo voltaic. They’ve a whole lot of pre-vetted photo voltaic installers competing for your online business, guaranteeing you get prime quality options and save 20-30% in comparison with going it alone. Plus, it’s free to make use of and also you gained’t get gross sales calls till you choose an installer and share your cellphone quantity with them.

Your customized photo voltaic quotes are straightforward to check on-line and also you’ll get entry to unbiased Power Advisers that will help you each step of the best way. Get began right here. –advert*

FTC: We use revenue incomes auto affiliate hyperlinks. Extra.